Describe 5 Tools Being Used in Sand Casting

A device used to measure high temperatures. The sand casting process involves the use of a furnace.

Instructions For Making Sand Casting Molds In Detail Step By Step

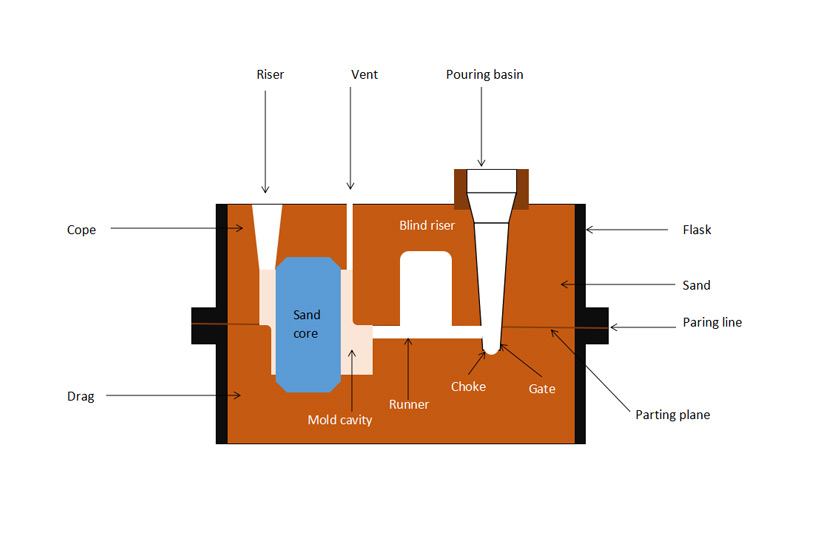

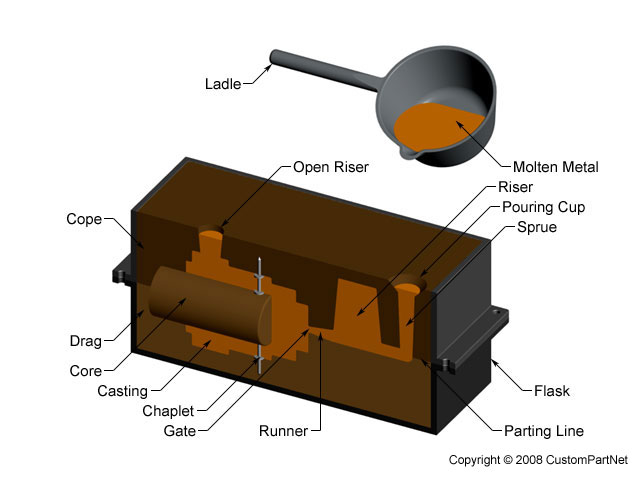

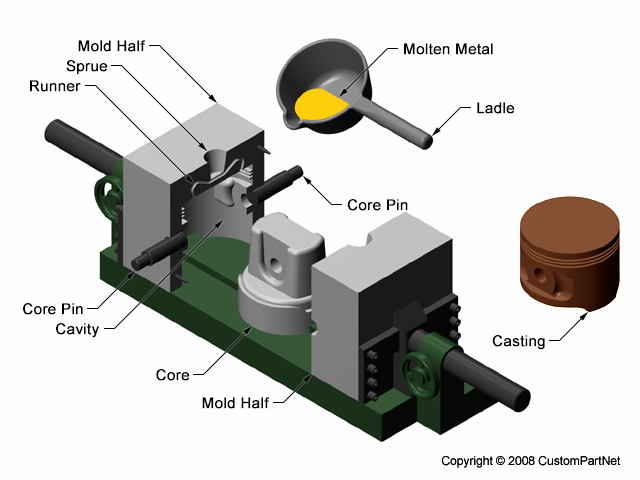

In sand casting sand is used to define the cavity inside a mold.

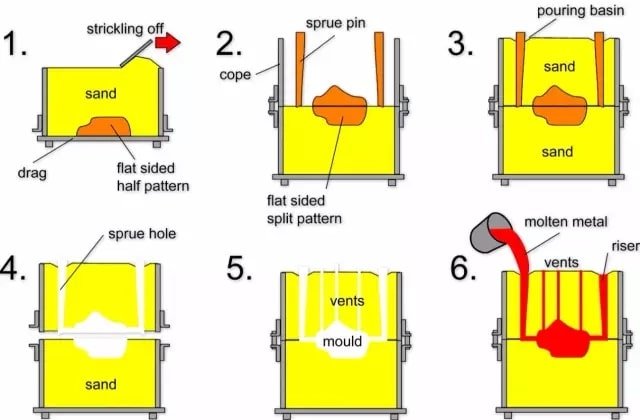

. Because the sand mold must be destroyed in order to remove the part called the casting sand casting typically has a low production rate. Aerators are used to loosen the sand and make it easier to mold. The size and shape of the casting is directly influenced by the mold.

6 Clay content test. 8 Compression shear test. Mainly Green or Natural and Synthetic Sands are used.

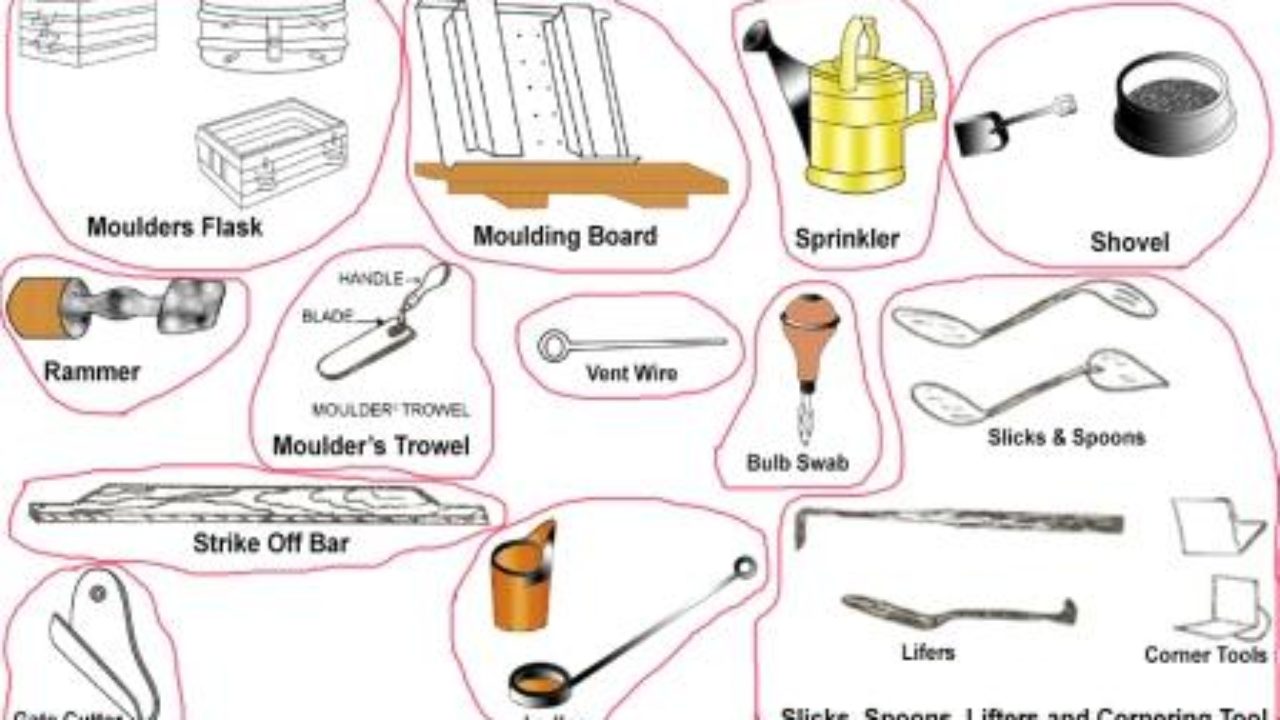

Sand cutters that operate over a heap on the foundry floor may be used instead of mullers. Mold can be used immediately for casting. Different types of Casting tools and equipment Hand riddle.

2 Mould hardness test. Molds made of sand are. Last but not least a big steal rod is used to lift the furnace lid off of the furnace once again by two people from opposing sides.

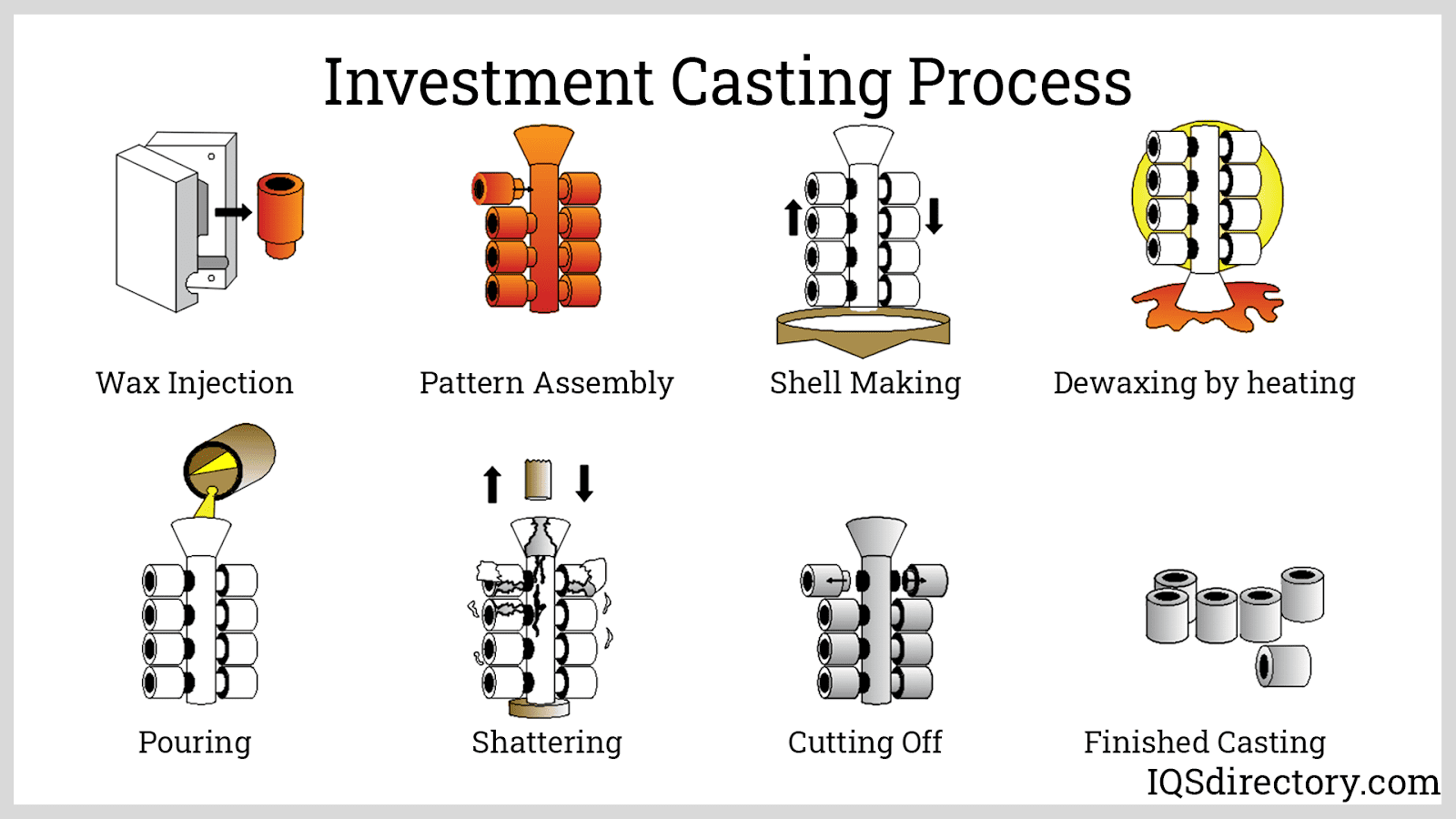

The term sand casting can also refer to an object produced via the sand casting process. Step 2 Set Up the Gating System. Other Expendable Mold Casting Shell Molding Vacuum Molding Expanded Polystyrene Process.

Mechanical tools are generally used in automated foundries. Over 60 of all metal castings are produced via sand casting process. Ending Mar 29 at 600PM PDT 3d 23h.

Sand Casting Mold Frame Cast Iron 2-Part Flask for Jewelry Metal Casting Tool. 3 Core hardness test. They are used for separating sand and another object that serve as obstacles when molding.

Cast Iron 2 Part Flask Mold for Delft Sand Casting Jewelry Making Tool. The operations include 1 trimming in which the sprues runners risers and flash are removed 2 core removal 3 surface cleaning 4 inspection 5 repair if. Which materials are commonly used for casting.

It is used for smoothening the surfaces of mould and also to repair the damaged portion of mould. 5 Sieve analysis. Before making the mold the properties of the molding sand should be checked.

Hand tools consist of the rammer shovel riddle vent wire lifter slick trowel mallet swab clamps gagger bellow etc. Sand casting also known as sand molded casting is a metal casting process characterized by using sand as the mold material. Sand castings are produced in specialized factories called foundries.

There are different types of molding sands. 1 Preparation of standard test specimen. Sand blasting equipments are the main cleaning equipments and there are mainly hook-type crawler transfer desktop shot blasting machines.

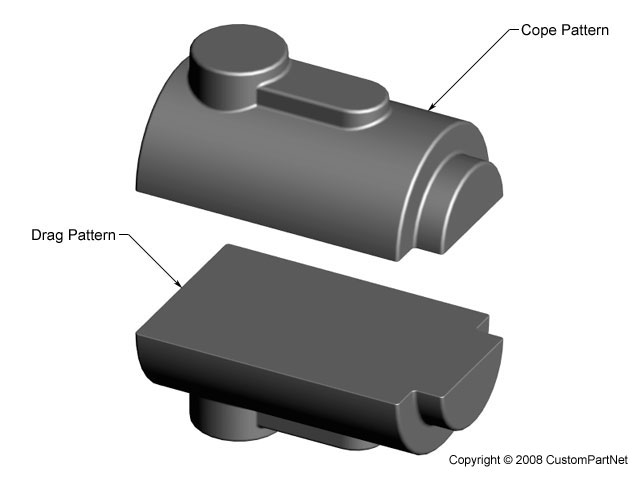

Breaking the mold and getting the casting. Come to TechShop Menlo Park and Ill. The type of pattern that has only one part.

They are used for moving or transferring the molding sand into the container molding box or flask. The type of pattern that consists of two or more parts used to make round or irregular molds. Step 1 Place Mold Pattern in Sand.

Metal casting is the process in which molten metal is poured into a mold and allowed to solidify into an object. 4 Moisture content test on foundry sand. Delivery of the sand to the molding floor may be by means of dump or scoop trucks or by belt conveyors.

Therefore manufacturing companies must create new molds to create metal products and components in specific sizes and shape. A machine used to mix sand for casting. It is used for repairing and finishing surfaces and to round corners of.

It is a metal sieve used for removing foreign materials such as stones nails etc from the moulding sand. Each type of sand is used in molding according to the cast materials and application of the materials. After sand blasting the castings will need workers to grind them by grinding tools to remove the burrs and sharp edges.

The first step of sand casting involves the placement of the mold pattern in sand. In addition sand is used to make any cores that are contained in the mold. The principal casting tools are hand tools containers and mechanical tools.

Testing of Mould Core sand. 7 Permeability test. For very large or heavy castings mold is often bakeddried in an oven to improve mold strength and rigidity.

Vintage Pattern Maker Foundry Sand Casting Floats Spoons Antique Tool. Mixture is placed in a core box and squeezed against the pattern to form a mold. It is used for packing or ramming the moulding sand in the moulding box.

The object that results from this process is also called a casting. Sand casting the most widely used casting process utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Sand bentonite clay coal and water.

What tools are used in casting.

Guide To Sand Casting Premier Engineered Products

Process Flow Chart Of Sand Casting 6 Download Scientific Diagram

10 Different Types Of Casting Process Machinemfg

Foundry Tools And Equipment List Names Images Marinerspoint

Types Of Sand Casting Tools And Equipment Studentlesson

Sand Casting Process Defects Design

Sand Casting An Overview Sciencedirect Topics

Sand Casting An Overview Sciencedirect Topics

Sand Casting Learn More About Sand Casting Process Youtube

Hand Tools Used In Foundry Shop Engineers Gallery

Patterns And Cores Sand Casting Youtube

Sand Casting Process Defects Design

Sand Casting Method Ganoksin Jewelry Making Community

The Lost Foam Casting Process Part One Total Materia Article

Sand Casting An Overview Sciencedirect Topics

What Is Casting Core Prints Use Of Core Prints

Comments

Post a Comment